HEAT EXCHANGER TUBES

A – Schlatter technology

B – BRIGHT METAL ultrasound technology (single junction point)

C – Malaguti technology

BRIGHT METAL heat exchangers use ultrasonic technology.

The use of ultrasonic welding for refrigeration has the following benefits:

- Only one weld is present, so there is a reduction of the possibility of leaks.

- Automation of the welding process with guarantee of product standardization.

- High mechanical resistance of copper-aluminum junction and sure sealing by the action of ultrasound.

- Total coverage of copper-aluminum junction with welding alloy which prevents access to air and moisture blocking any corrosion processes.

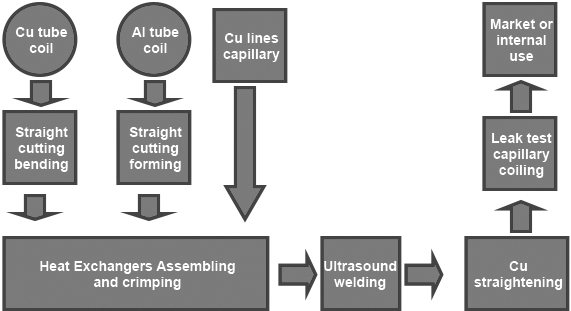

Flow chart for the process of the ULTRASOUND technology

PRODUCTION STEPS

Please fill in this form if you have any inquiries and we will reply to you as soon as possible.